Call Us :- 07971670836

Showroom

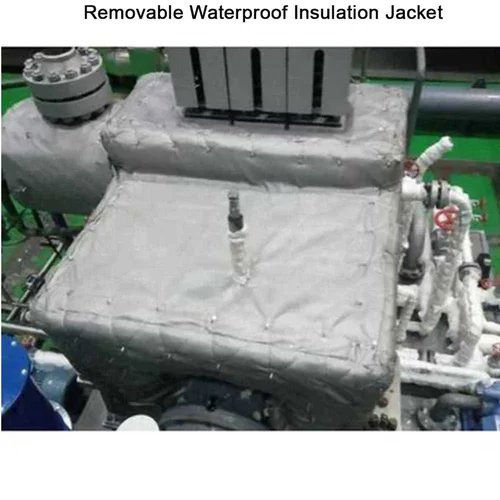

Reusable/Removable Insulation Jacket can as the names clues be used times and again and is easily recyclable too. The jacket is also very helpful in maintaining the temperature of the item en stored in any end product.

Insulation Rolls are offered in rolls of any desired specifications which are very effective in maintenance and balancing the temperature of any given area. The rolls can be availed in very pocket friend;y prices.

Insulation Mattress are very soft and flexible. These are very helpful in trapping the heat and also saving the end products from bursting due to the extreme temperatures inside. These take care of the heat loss problem too.

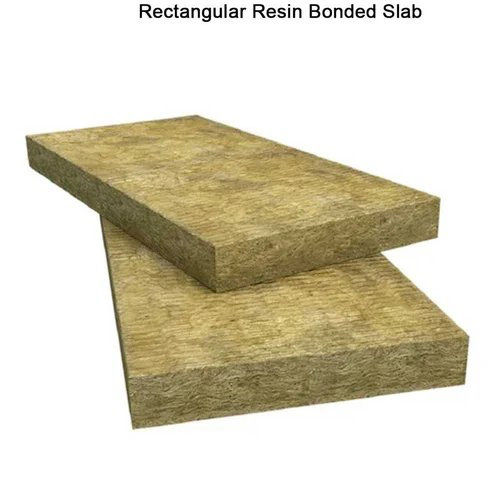

Resin Bonded Slabs comprises of finest fabrics and are suitable fro both low and high temperatures. These are excellent noise absorbers as well along with being insulators fro walls in auditoriums.

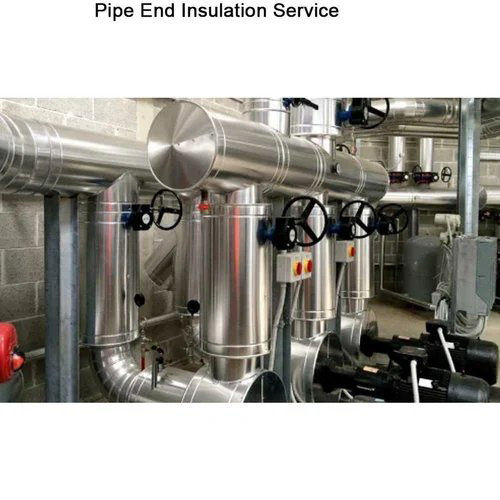

Insulation of Pipe Phase are very flexible and versatile enough to cover all kinds of pipes and structure whether plain or irregular. These ensures the ta the pipes carrying hot substance do not burst due to excess heat and vice verse in the case of cold pipes.

Highly suitable for irregular surfaces like bends of pipes, Removable & Reusable Insulation Jacket Pipe & Bends are demanded on a large scale. The products are well filled wool derived from rocks.

We are an expert in providing Insulation Services, by which we ensure the absolute protection of the surfaces of your products or any given area with the help of our latest tools and technologies.

Noise Management Services are conducted under the supervision of a very talented team of experts. The services ensures to stop the unrequited vibration and sound coming from any ongoing process and in very cost effective prices.

Lacing Hooks & Lock Washers are used to secure tie various other insulation means such as blankets. These tend to fasten the insulation and are made up of stainless steel.

Pipe Covers are basically the foam sleeves that covers the pipes from the unfavorable climatic conditions and reactions. Apart from protecting and maintaining the temperature of the pipes, these covers offers great grip to the user.

We are a Gujarat, India-based manufacturer and supplier of premium-grade Turbine Insulation products that are designed to protect HVAC elements as well as help to improve overall thermal efficiency. Buy from us these durable and cost-efficient insulation materials at a reasonable and low price.

Insulation materials are manufactured to provide thermal efficiency, energy savings, and safety across industrial, commercial, and residential applications. Produced using high-quality components, they offer durability, heat resistance, and easy installation. These materials ensure reliable insulation, reduced energy loss, and protection in high-temperature and harsh operating environments.

Insulation jackets are developed to cover equipment and piping, offering removable and reusable thermal protection. Constructed with durable and flexible materials, they provide excellent heat retention, safety, and energy efficiency. Suitable for industrial plants, refineries, and manufacturing units, insulation jackets enable easy maintenance while reducing energy consumption.

Insulation covers are designed to shield equipment and machinery from heat loss while ensuring safety. Produced with high-grade materials, they deliver resistance to temperature extremes and mechanical wear. These covers are ideal for boilers, tanks, and pipes, providing energy-efficient solutions in demanding industrial and commercial settings.

Insulation pipes are manufactured to deliver efficient thermal protection for fluid and gas transport systems. Constructed with high-density materials, they provide heat retention, corrosion resistance, and dimensional stability. Widely used in HVAC, chemical, and industrial applications, insulation pipes enhance energy efficiency and operational safety.

Lacing anchors are engineered to secure insulation blankets, mats, and jackets on pipes, tanks, and vessels. Made from durable and corrosion-resistant materials, they provide strong holding power and easy installation. These anchors ensure long-term stability and safety in high-temperature industrial environments.

Heating jackets are developed to maintain controlled temperatures for equipment and piping in industrial processes. Manufactured using robust thermal materials and flexible designs, they deliver uniform heat distribution, energy efficiency, and operational reliability. Heating jackets are widely used in chemical, food, and manufacturing industries.

Lacing hooks and washers are produced to provide secure attachment of insulation blankets and jackets. Designed with high-strength and corrosion-resistant materials, they ensure easy assembly, long-lasting performance, and stability. These components are ideal for thermal insulation systems in industrial and commercial installations.

Ceramic fibre blankets are manufactured to offer superior thermal insulation, high-temperature resistance, and durability. Made from premium-grade ceramic fibres, they provide excellent heat retention and fire protection. Widely applied in furnaces, kilns, and refractory linings, these blankets enhance energy efficiency and safety in industrial operations.

Insulated pipes are engineered to prevent heat loss, maintain temperature, and protect fluid or gas transport systems. Constructed using high-quality insulation materials and durable outer jackets, they offer corrosion resistance and mechanical strength. These pipes are widely used in industrial, commercial, and residential thermal applications.